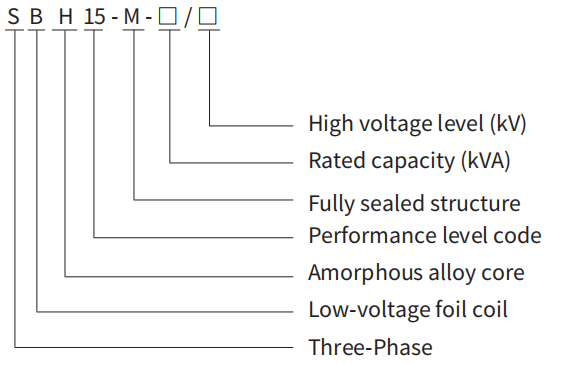

SBH15 Series Amorphous Alloy Oil Immersed Transformer

Product introduction

Sbh15 series amorphous alloy transformer is a kind of oil immersed transformer with low loss and high energy efficiency. The core of the product is made of amorphous alloy strip, and its no-load loss is more than 70% lower than that of the traditional transformer with silicon steel sheet as core. It is a new generation of energy-saving, safe, green and environment-friendly high-tech product.

The product can replace the ordinary oil immersed transformer and is mainly used in high-rise buildings, commercial centers, subways, airports, stations, industrial and mining enterprises, power plants and other electric fields.

Model Meaning

Standards

GB/T 1094.1-2013 Power transformers - Part 1: General

GB/T 1094.2-2013 Power transformers - Part 2: Temperature rise for liquid-immersed transformers GB/T 1094.3-2017 Power transformers - Part 3:Insulation levels, dielectric tests and external clearances in air GB/T 1094.5-2008 Power transformers - Part 5: Ability to withstand short circuit

GB/T 1094.10-2003 Power transformers--Part 10: Determination of sound levels IEC60076-1:2011 Power transformers - Part 1: General

IEC60076-2:2011 Power transformers - Part 2: Temperature rise for liquid-immersed transformers

IEC 60076-3:2013+AMD1:2018 Power transformers - Part 3: Insulation levels, dielectric tests and external clearances in air IEC 60076-5:2006 Power transformers - Part 5: Ability to withstand short circuit

IEC 60076-10:2016 Power transformers - Part 10: Determination of sound levels

Normal Environment conditions

1.Ambient Temperature: No more than +40℃

No less than -25℃ The monthly average temperature is no more than +30℃ The yearly average temperature is no more than +20℃

2.Altitude: No more than 1000m. 3.The power supply voltage's wave is similar to sine wave. 4.Three-phase power supply voltage is approximately symmetrical.

5.The total harmonic content of load current shall not exceed 5% of ratedcurrent; 6.Installation Site: Indoor or outdoor.

Product characteristics

1.The core is made of amorphous alloy strip, with low no-load loss.

2.The positioning structure is added to the body to avoid displacement during transportation. At the same time, all fasteners are equipped with fastening nuts to ensure that the fasteners are not loose during long-term operation.

3.This product is a fully sealed structure. The vacuum oil filling process is adopted when the transformer is packaged, which completely removes the moisture in the transformer, ensures the isolation of the transformer oil from the outside air, prevents the aging of the oil, and improves the operation reliability of the transformer. The product is equipped with pressure relief valve, signal thermometer, gas relay and so on to ensure the safe operation of the transformer.

4.The transformer oil tank is composed of corrugated wall, and the surface is sprayed with dust and the paint film is firm. Corrugated heat sink not only has cooling function, but also has "breathing" function. The elasticity of corrugated heat sink can compensate the change of transformer oil volume caused by temperature rise and fall. Therefore, there is no oil conservator in the fully sealed transformer, which reduces the overall height of the transformer.

5.The product is beautiful in appearance, small in volume and small in floor area. It is an ideal maintenance free product.

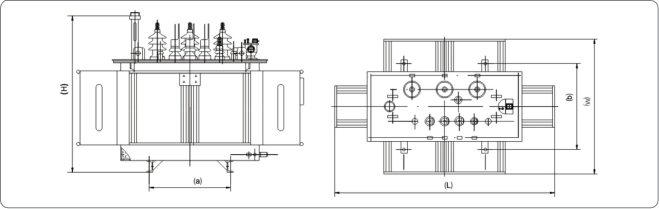

SBH15 Technical Parameter

|

caRpaatecdity (kvA)30 |

Voltage combination tHiggeh Taapnpging Low(vol)tage | cognrnoeucpted label |

diNssoi-ploaatidon (w)33 |

dissLiopaadtion (W)145℃ 630/600 | Ncuor-rIoeandt (%)1.50 | Imvpoeltdaagnece (%) | Outline dimension Length t(L)x wimdtmh )(B)x |

HorViGzoanutgaelland(eratxicba)400×550 |

W(ekig)ht 680 | ||

| vol a (kV) | r e |

kV |

heigh (H)( 950×620×10401060×770×1070) | ||||||||

|

50 |

66.3 61.06 1101.5 | ±2±×52.5 | 0.4 | Dyn11 |

43 |

910/870 |

1.20 |

4.0 |

|

400×660 |

890 |

|

63 |

50 |

1090/1040 |

1.10 |

1240×920×1200 |

550×870 |

1030 | |||||

|

80 |

60 |

1310/1250 |

1.00 |

1240×920×1200 |

550×870 |

1170 | |||||

|

100 |

75 |

1580/1500 |

0.90 |

1280×920×1200 |

550×870 |

1230 | |||||

|

125 |

85 |

1890/1800 |

0.80 |

1320×940×1200 |

660×870 |

1400 | |||||

|

160 |

100 |

2310/2200 |

0.60 |

1340×940×1200 |

660×870 |

1470 | |||||

|

200 |

120 |

2730/2600 |

0.60 |

1340×940×1200 |

660×870 |

1540 | |||||

|

250 |

140 |

3200/3050 |

0.60 |

1370×1120×1260 |

660×1070 |

1720 | |||||

|

315 |

170 |

3830/3650 |

0.50 |

1370×1120×1330 |

660×1070 |

2000 | |||||

|

400 |

200 |

4520/4300 |

0.50 |

1520×1190×1360 |

820×1070 |

2400 | |||||

|

500 |

240 |

5410/5150 |

0.50 |

1890×1220×1470 |

820×1070 |

2950 | |||||

|

630 |

320 |

6200 |

0.30 |

1960×1210×1550 |

820×1070 |

3500 | |||||

|

800 |

380 |

7500 |

0.30 |

4.5 |

2030×1310×1560 |

820×1070 |

4100 | ||||

|

1000 |

450 |

10300 |

0.30 |

2540×1350×1800 |

820×1070 |

5550 | |||||

|

1250 |

530 |

12000 |

0.20 |

2080×1540×1970 |

1070×1475 |

6150 | |||||

|

1600 |

630 |

14500 |

0.20 |

2560×1690×2380 |

1070×1475 |

6600 | |||||

|

2000 |

750 |

18300 |

0.2 |

2660×1800×2400 |

1070×1475 |

6950 | |||||

|

2500 |

900 |

21200 |

0.2 |

5 |

2720×1800×2460 |

1070×1475 |

7260 | ||||