OEM High Quality Molded Case Current Transfomer Manufacturer – S- M. L Series Of Oil Immersed Power Transformer With Three Dimensional Wound Core – Changan Group

OEM High Quality Molded Case Current Transfomer Manufacturer – S- M. L Series Of Oil Immersed Power Transformer With Three Dimensional Wound Core – Changan Group Detail:

Product introduction

S □ -M·L series three-dimensional wound core oil immersed transformer produced by the company is a new generation transformer product with more reasonable structure, lower operation noise, better performance and stronger reliability. The product breaks through the traditional plane structure and adopts three-phase symmetrical three-dimensional structure. The three cores are arranged in an equilateral triangle, and the length of the three magnetic circuits is consistent. It has the characteristics of high efficiency and low loss. It can save a lot of power consumption and operating costs, and has significant social benefits. It has been widely used in power plants, substations, industrial and mining enterprises, ports, airports and other places.

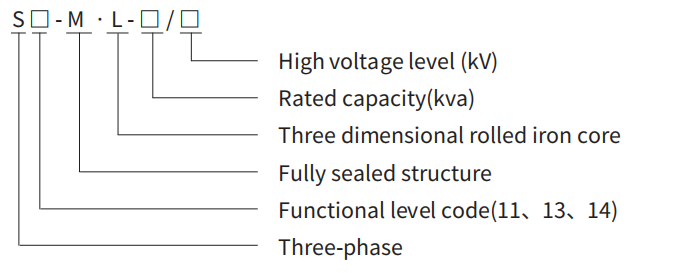

Model Meaning

Standards

GB/T 1094.1-2013 Power transformers – Part 1: General

GB/T 1094.2-2013 Power transformers – Part 2: Temperature rise for liquid-immersed transformers GB/T 1094.3-2017 Power transformers – Part 3:Insulation levels, dielectric tests and external clearances in air GB/T 1094.5-2008 Power transformers – Part 5: Ability to withstand short circuit

GB/T 1094.10-2003 Power transformers–Part 10: Determination of sound levels IEC60076-1:2011 Power transformers – Part 1: General

IEC60076-2:2011 Power transformers – Part 2: Temperature rise for liquid-immersed transformers

IEC 60076-3:2013+AMD1:2018 Power transformers – Part 3: Insulation levels, dielectric tests and external clearances in air IEC 60076-5:2006 Power transformers – Part 5: Ability to withstand short circuit

IEC 60076-10:2016 Power transformers – Part 10: Determination of sound levels

Normal Environment conditions

1.Ambient Temperature: No more than +40℃

1.No less than -25℃ The monthly average temperature is no more than +30℃ The yearly average temperature is no more than +20℃

2.Altitude: No more than 1000m. 3.The power supply voltage’s wave is similar to sine wave. 4.Three-phase power supply voltage is approximately symmetrical.

5.The total harmonic content of load current shall not exceed 5% of ratedcurrent; 6.Installation Site: Indoor or outdoor.all not exceed 5% of ratedcurrent;

6.Installation Site: Indoor or outdoor.

Product characteristics

Optirmoizdeud: the three-phase magnetic circuit length of three-dimensional wound core is completely equal, the sum of the three-phase magnetic circuit length is the shortest, the three-phase magnetic circuit is completely symmetrical, and the three-phase no-load current is completely balanced.

2.Low loss and remarkable energy-saving effect: the magnetization direction of three-dimensional coil core is completely consistent with the rolling direction of silicon steel sheet, the magnetic flux distribution is uniform throughout the magnetic circuit, and there is no obvious distortion of magnetic flux density in high resistance area and joint. On the premise of the same material, the process coefficient of core loss is significantly lower than that of laminated core, the core loss can be reduced by 10% – 20%, and the no- load loss can be reduced by 25% – 35%.

3.Low noise: as the three-dimensional core is made of silicon steel strip in a special core winding machine, there is no seam, so it will not produce the noise caused by the magnetic circuit discontinuity as the laminated core. Therefore, the voice of the product is greatly reduced, almost reaching the state of environmental protection mute, which is most suitable for indoor and residential use.

4.Strong overload capacity: the no-load loss and no-load current of this type of transformer are very small, so the calorific value of the product itself is very low; in addition, the three-phase coils are arranged in three rectangle structure, forming a central natural airway – “exhaust chimney” between the coils. Because the temperature difference between the upper and lower yokes is 30-40 ℃ , strong air convection is generated, and the cold air flows from the bottom to the central passage in addition, the heat radiates out from the inner slope of the upper yoke, and the heat generated by the transformer is quickly taken away in the natural circulation.

5.Compact structure and small occupation: the three-dimensional iron core makes the product compact in structure, the plane occupation area of the body is reduced by 10-15% compared with the traditional products, and the body height is reduced by 10- 20%.

S11-M·L Technical Parameter

|

Ca(kpvaAc)ity 30 |

Installation dimensions | Low voltage line terminal | Low voltage 0 line terminal | ||||||||||

| E1 | E2 |

D |

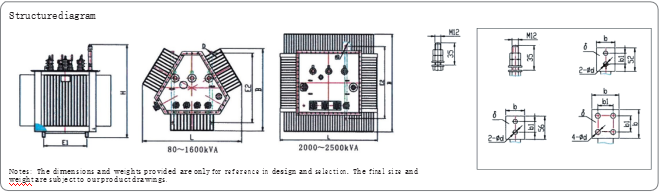

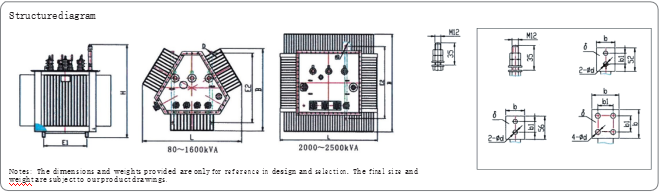

Graphical |

b |

b1 |

d |

f |

Graphical |

b |

b1 |

d |

f | |

|

6530 |

380 | 550 |

19 |

2 |

35 |

26 |

12.5 | 8 |

2 |

35 |

26 |

12.5 | 8 |

|

80 |

380 | 550 |

19 |

2 |

35 |

26 |

12.5 | 8 |

2 |

35 |

26 |

12.5 | 8 |

|

100 |

38 | 55 | |||||||||||

|

5 |

400 | 660 |

19 |

2 |

35 |

26 |

12.5 | 8 |

2 |

35 |

26 |

12.5 | 8 |

|

160 |

2 |

||||||||||||

| 400 | 660 |

19 |

2 |

35 |

26 |

12.5 | 8 |

3 |

35 |

26 |

12.5 | 8 | |

|

250 |

40 | 66 | |||||||||||

|

430105 |

550 | 820 |

19 |

3 |

46 |

26 |

12.5 | 10 |

3 |

46 |

26 |

12.5 | 10 |

|

43 |

8406 |

4256 |

42 |

30 |

3 |

46 |

26 |

42 |

30 | ||||

|

6530 |

550 | 820 |

19 |

1 .5 | 1 |

4 |

80 |

45 |

1 .5 | 1 | |||

|

0 |

|||||||||||||

|

800 |

550 | 820 |

19 |

4 |

80 |

45 |

14.5 | 13 |

4 |

80 |

45 |

14.5 | 13 |

|

1000 |

90 | ||||||||||||

|

6205 |

550 | 1070 |

19 |

4 |

100 |

45 |

18 | 17 |

4 |

80 |

45 |

14.5 | 13 |

|

1 0 |

6505 | 3007 | |||||||||||

| 0 | 1 0 |

19 |

4 |

100 |

45 |

18 | 17 |

4 |

100 |

45 |

18 | 17 | |

|

2500 |

600 | 1300 |

19 |

4 |

125 |

50 |

19 | 15 |

4 |

100 |

45 |

18 | 17 |

S13-M·L Technical Parameter

| caRpaatecdity (kvA)

3 |

Voltage combination High kvVo)ltage Taapping Low vol)tage |

Cognrnoeucpted label |

diNssoi-ploaatidon (w) 80 |

dissLiopaadtion (W)75℃63 60 |

Ncuor-rIoeandt (%) 02.3 |

Imvp(e%da)nece oltag | Spownedr level(dB) |

ExteIrniostraslilz4e-(ΦLx1W8 xH) (mm) 69 890 |

WTeoitgahlt (kg) 257 |

||

|

( |

r nge |

(kV |

|||||||||

|

50 |

66.6 1100.5 11 | ±2×52.5 | 0.4 | DYyynn101 Yzn11 | 100 | 910/870 |

0. 4 |

4 |

48 |

745×680×915 | 335 |

|

63 |

9 4 | 945×82 1020 | |||||||||

|

80 |

130 | 1310/1250 |

0.22 |

49 |

1045×705×995 | 490 | |||||

|

0 |

8 |

0.21 |

49 |

890 9 05 | 49 | ||||||

| 125 | 170 | 1890/1800 |

0.2 |

50 |

905×815×1040 | 620 | |||||

| 16 | 1 | 20 0 0 |

5 |

||||||||

| 200 | 240 | 2730/2600 |

0.18 |

52 |

1075×930×1115 | 780 | |||||

| 250 | 29 | 0 |

0 |

985 | |||||||

| 315 | 340 | 3830/3650 |

0.16 |

54 |

1145×990×1275 | 1150 | |||||

| 4 | 452 430 | 1260×945×1250 |

50 |

||||||||

| 500 | 480 | 5410/5150 |

0.16 |

56 |

1320×1140×1325 | 1505 | |||||

| 63 | 57 | 62 | 25 90 |

0 |

|||||||

| 800 | DYyynn101 | 700 | 7500 |

0.15 |

4.5 |

58 |

1500×1300×1485 | 2470 | |||

|

0 |

83 |

3 |

58 |

85 370 54 | 269 | ||||||

| 1250 | 970 | 12000 |

0.13 |

60 |

1670×1445×1650 | 3245 | |||||

| 16 |

7 |

5 |

35 505 | 3995 | |||||||

| 2000 | 1550 | 18300 |

0.11 |

62 |

1890×1620×1720 | 4800 | |||||

| 2500 | 1830 | 21200 |

0.11 |

5 |

62 |

1940×1670×1860 | 5540 | ||||

| Ca(kpvaAc)ity 30 | Installation dimensions | Low voltage line terminal | Low voltage 0 line terminal | ||||||||||

|

E1 |

E2 | D |

Graphical |

b |

b1 |

d |

f |

Graphical |

b | b1 |

d |

f | |

|

6530 |

380 |

550 | 19 |

2 |

35 |

26 |

12.5 |

8 |

2 |

35 | 26 |

12.5 |

8 |

|

80 |

380 |

550 | 19 |

2 |

35 |

26 |

12.5 |

8 |

2 |

35 | 26 |

12.5 |

8 |

|

2050 |

4308 |

6565 | |||||||||||

| 1 |

0 |

0 |

19 |

2 |

35 |

26 |

12.5 |

8 |

2 |

35 | 26 |

12.5 |

8 |

| 2106 |

2 |

32 |

|||||||||||

|

0 |

400 |

660 | 19 |

3 |

35 |

26 |

12.5 |

8 | 35 | 26 |

12.5 |

8 | |

| 321550 |

5450 |

8626 | |||||||||||

|

0 |

0 |

19 |

3 |

46 |

26 |

12.5 |

10 |

3 |

56 | 26 |

12.5 |

10 | |

| 4 |

43 |

8406 |

4256 |

42 |

30 |

3 |

56 | 26 |

42 |

30 | |||

| 500 |

550 |

820 | 19 |

1 .5 |

1 |

4 |

80 | 45 |

1 .5 |

1 | |||

| 63 | |||||||||||||

| 800 |

550 |

820 | 19 |

4 |

80 |

45 |

14.5 |

13 |

4 |

80 | 45 |

14.5 |

13 |

|

0 |

90 | ||||||||||||

| 1250 |

550 |

1070 | 19 |

4 |

100 |

45 |

18 |

17 |

4 |

80 | 45 |

14.5 |

13 |

| 2106 |

6505 |

3007 | |||||||||||

|

00 |

0 |

1 0 | 19 |

4 |

100 |

45 |

18 |

17 |

4 |

100 | 45 |

18 |

17 |

| 2500 |

600 |

1300 | 19 |

4 |

125 |

50 |

19 |

15 |

4 |

100 | 45 |

18 |

17 |

S14-M·L Technical Parameter

| caRpaatecdity (kvA)

3 |

Voltage combinationtHiggeh Taapnpging Low vol)tage | Cognrnoeucpted label |

diNssoi-ploaatidon (w) 80 |

dissLiopaadtion (W)75℃505 80 |

Ncuor-rIoeandt (%) 02.3 |

Imvpoeltdaagnece (%) | Spownedr level(dB) |

ExteIrniostraslilz4e-(ΦLx1W8 xH) (mm) 69 890 |

WTeoitgahlt (kg) 257 |

||

| vol a (kV) | r e |

(kV |

|||||||||

|

50 |

66.6 1100.5 11 | ±2×52.5 | 0.4 | DYyynn101 Yzn11 | 100 | 730/695 | 0. 4 | 4 |

48 |

745×680×915 | 335 |

|

63 |

0857 1803 | 945×82 1020 | |||||||||

|

80 |

130 | 1 0/ 00 | 0.22 |

49 |

1045×705×995 | 490 | |||||

|

0 |

6 0 | 0.21 |

49 |

890 9 05 | 49 | ||||||

| 125 | 170 | 1510/1440 | 0.2 |

50 |

905×815×1040 | 620 | |||||

| 16 | 185 176 | 20 0 0 |

5 |

||||||||

| 200 | 240 | 2180/2080 | 0.18 |

52 |

1075×930×1115 | 780 | |||||

| 250 | 29 | 25 44 |

0 |

985 | |||||||

| 315 | 340 | 3060/2920 | 0.16 |

54 |

1145×990×1275 | 1150 | |||||

| 4 | 361 344 | 1260×945×1250 |

50 |

||||||||

| 500 | 480 | 4330/4120 | 0.16 |

56 |

1320×1140×1325 | 1505 | |||||

| 63 | 57 | 496 | 25 90 |

0 |

|||||||

| 800 | DYyynn101 | 700 | 6000 | 0.15 | 4.5 |

58 |

1500×1300×1485 | 2470 | |||

|

0 |

83 | 824 |

58 |

85 370 54 | 269 | ||||||

| 1250 | 970 | 9600 | 0.13 |

60 |

1670×1445×1650 | 3245 | |||||

| 16 |

7 |

35 505 | 3995 | ||||||||

| 2000 | 1550 | 14600 | 0.11 |

62 |

1890×1620×1720 | 4800 | |||||

| 2500 | 1830 | 16900 | 0.11 |

5 |

62 |

1940×1670×1860 | 5540 | ||||

| Ca(kpvaAc)ity 30 | Installation dimensions | Low voltage line terminal | Low voltage 0 line terminal | ||||||||||

|

E1 |

E2 | D |

Graphical |

b |

b1 |

d |

f |

Graphical |

b | b1 |

d |

f | |

|

6530 |

380 |

550 | 19 |

2 |

35 |

26 |

12.5 |

8 |

2 |

35 | 26 |

12.5 |

8 |

|

80 |

380 |

550 | 19 |

2 |

35 |

26 |

12.5 |

8 |

2 |

35 | 26 |

12.5 |

8 |

|

2050 |

4308 |

6565 | |||||||||||

| 1 |

0 |

0 |

19 |

2 |

35 |

26 |

12.5 |

8 |

2 |

35 | 26 |

12.5 |

8 |

| 2106 |

2 |

32 |

|||||||||||

|

0 |

400 |

660 | 19 |

3 |

35 |

26 |

12.5 |

8 | 35 | 26 |

12.5 |

8 | |

| 321550 |

5450 |

8626 | |||||||||||

|

0 |

0 |

19 |

3 |

46 |

26 |

12.5 |

10 |

3 |

56 | 26 |

12.5 |

10 | |

| 4 |

43 |

8406 |

4256 |

42 |

30 |

3 |

56 | 26 |

42 |

30 | |||

| 500 |

550 |

820 | 19 |

1 .5 |

1 |

4 |

80 | 45 |

1 .5 |

1 | |||

| 63 | |||||||||||||

| 800 |

550 |

820 | 19 |

4 |

80 |

45 |

14.5 |

13 |

4 |

80 | 45 |

14.5 |

13 |

|

0 |

90 | ||||||||||||

| 1250 |

550 |

1070 | 19 |

4 |

100 |

45 |

18 |

17 |

4 |

80 | 45 |

14.5 |

13 |

| 2106 |

6505 |

3007 | |||||||||||

|

00 |

0 |

1 0 | 19 |

4 |

100 |

45 |

18 |

17 |

4 |

100 | 45 |

18 |

17 |

| 2500 |

600 |

1300 | 19 |

4 |

125 |

50 |

19 |

15 |

4 |

100 | 45 |

18 |

17 |

Product detail pictures:

Related Product Guide:

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for OEM High Quality Molded Case Current Transfomer Manufacturer – S- M. L Series Of Oil Immersed Power Transformer With Three Dimensional Wound Core – Changan Group , The product will supply to all over the world, such as: Japan, Swiss, Sheffield, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!